Ok, about a months worth of stuff.

First off, here is what happened before the images start. We removed the pistons and rods from the engine and strapped the head in each of its two positions at the front and back of the block and double checked the we liked the placement of the combustion chamber over the cylinder. Also the there was proper ( in our opinions ) valve clearance. Then we installed center punches in the block, placed the head and whumped it with a rawhide hammer. Partly to mark it with the center punches aka the new head bolt boss locations, partly because we sort of dislike it for all the trouble it is probably bound to cause us. Bad head.

Then rich made some tooling plates to support the head on the mill

Here are some pics

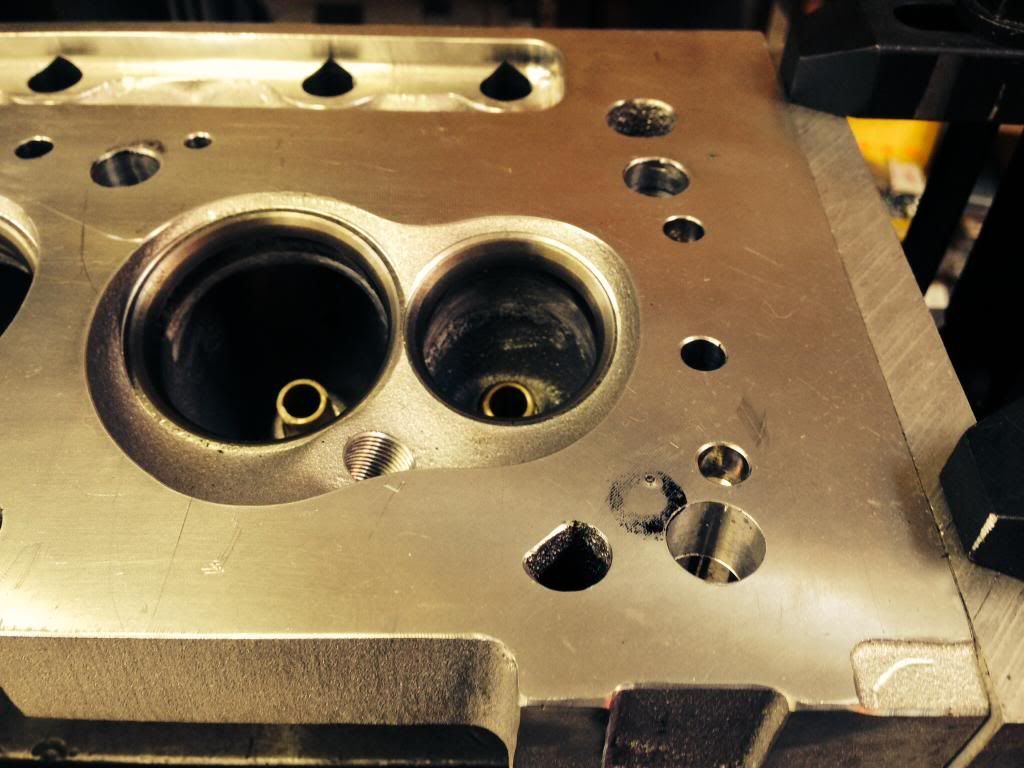

^Here is the center punch mark, one of them.

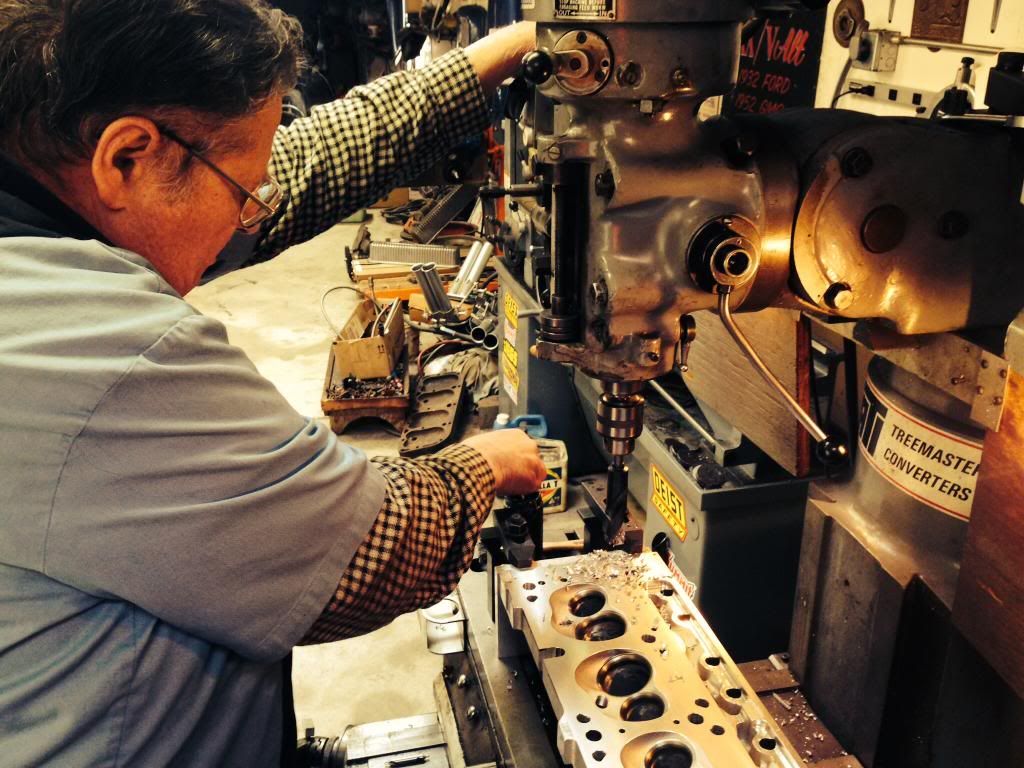

^Here is the head with the tooling plates bolted on the mill ready to machine

^Rich checking on what the hell I am doing with his mill, brushing some chips away

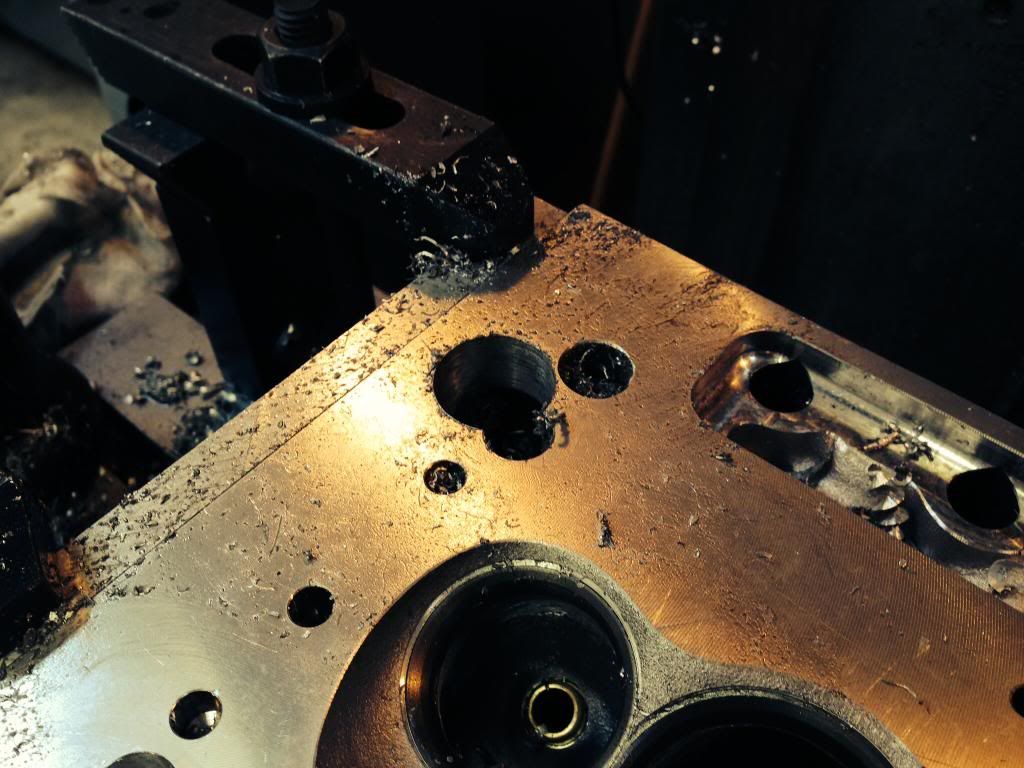

^The first boss drilled. It is a 1" DIA hole

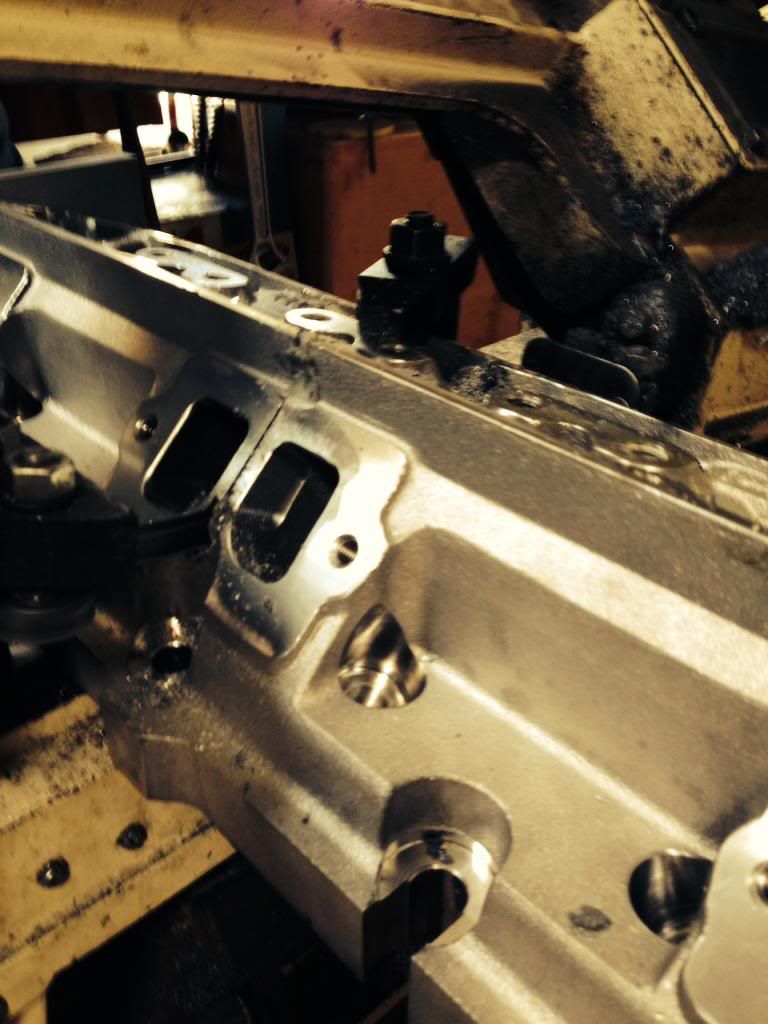

^Jump forward, bosses tapped into holes, testing fit on block. Front and read of block/head

TO THE BAND SAW!!!! Quickly before we think too much about it!

^Rich made some custom "T" nuts so we could remove the saws built in vice and clamp the head right to the saw. Here he is removing the vice/guide parts

^Look at this unsuspecting victi....fine piece of future racing equipment

^Clamped to the saw, starting the cut

^Whistle, whistle, tap foot........getting closer

^Almost there. The observant may notice we had to change the clamp on the back side.....the saw hit it and could cut any deeper. No problem, we used a different clamp and continued

^Ta Da!!!!!!!!!

I stopped and picked up some 6061 bar stock for the spacer and for an adapter/spacer on the intake side. More to come!