Batteries. It's all about the batteries...

Actually everything has to work together. There's no point in having a very sophisticated motor/controller system then try to feed it with flashlight batteries. Likewise, there's no point in choosing batteries that are a lot more capable than needed for the rest of the system. The analogy I make is that the batteries are like the fuel supply system in an internal combustion engine, the motor is like the engine and the controller is like the carburetor. Any one of them can limit performance depending on their individual characteristics.

I went through a lot of investigation before choosing Enerdel, an Indiana-based company. They make a pretty sophisticated lithium nickel-manganese-cobalt (NMC) cell that is a good compromise between power, energy and safety. They're used in a lot of commercial applications like hybrid-buses. They're also the battery used by Lightning Motorcycles. They come in two flavors: "energy" or "power" modules.

There's a lot of different types of lithium batteries out there today, generically known as "lithium ion". Lithium Iron Phosphate (LiFePO4) is used in a lot of automobile conversions. They are a pretty safe chemistry and typical format is prismatic (rectangular) which simplifies installation, although they are not as energy or power dense as other types. Lithium Polymer (LiPo's) are commonly used in RC vehicles because they are very power dense but they are more susceptible to damage if over or under charged. LiFePO4's have a nominal voltage of about 3.3 volts per cell and stay fairly flat when discharged i.e. the discharge curve is pretty flat as they give up current, then dives at the end. Most LiPo's have a nominal voltage of 3.7 vpc and their discharge curve is not as flat. The Enerdel NMC's have a discharge curve that mimics lead-acid in many respects. On this bike I "lose" about one volt for each mile traveled. I generally charge to 4.1 volts per cell for a starting voltage of about 393. After 50 miles pack voltage will generally be around 345 or so. It's a pretty convenient way to keep track of how much further I might go. The trick is to avoid the ends of the discharge curve. Don't overcharge and don't suck them down too far.

Enerdels are shipped in 12s2p modules. Two cells are hooked together in parallel then twelve of these are hooked in series in one block. I purchased eight such blocks or modules.

The aluminum bits at the end are connected to sheets of aluminum separating each cell. This conducts heat away from the cell for passive dissipation. Enerdels are pretty unique in that the positive tab (connection point) is at one end of the cell with the negative tab at the other. Supposedly this keeps heat generation uniform.

With the plastic finger guards removed you can see the busbars which make the series connection.

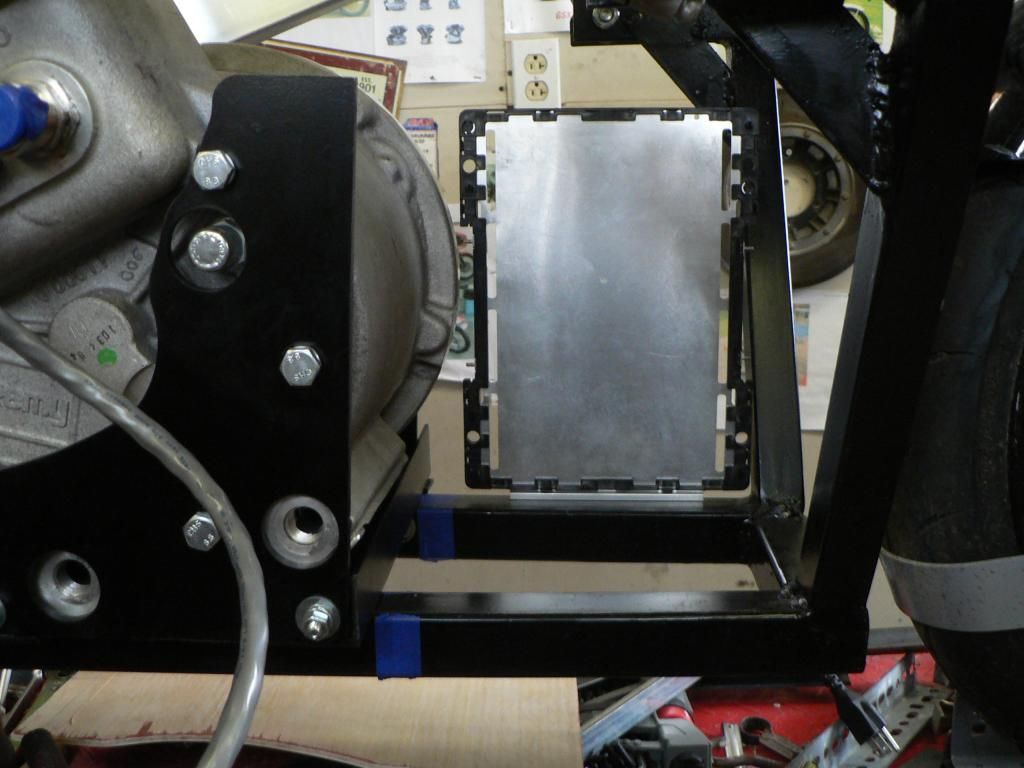

The cells in each module are clamped together by four insulated aluminum bolts with a nut on each end. Things are pretty tight in front of the motor. This is where I want to install the first subpack.