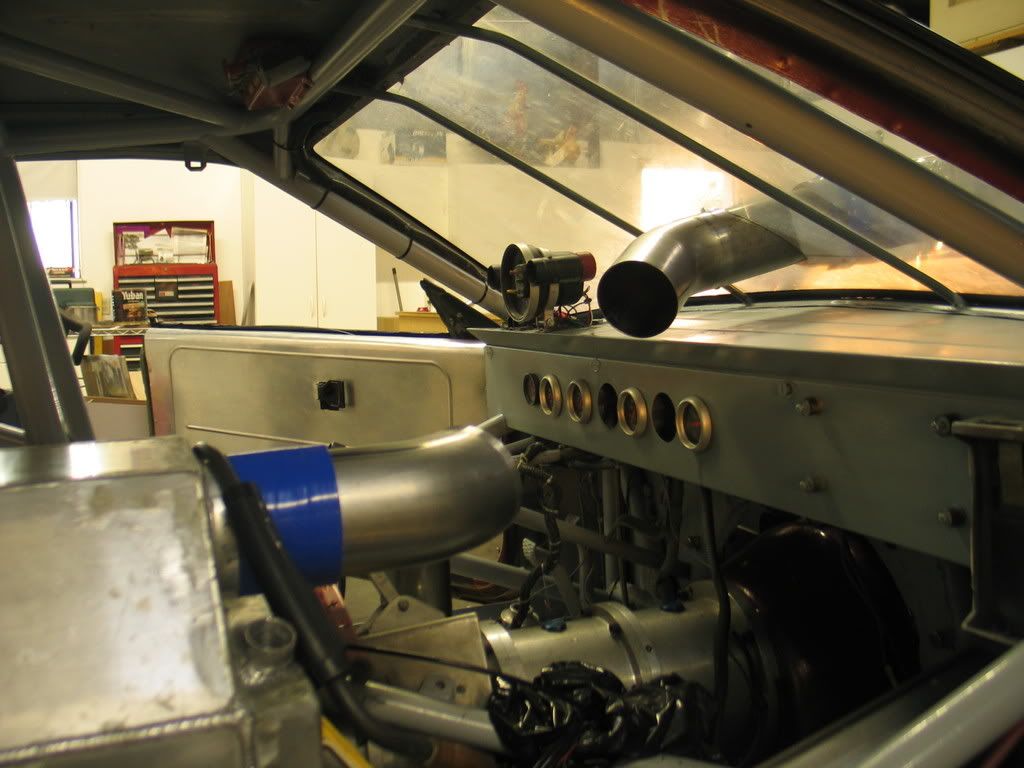

The air intake is all welded up and ground down. We are getting ready to work on the blower tubing that goes through the window.

taping the window to get a sketch to follow.

Making up a template just to make sure this shape will work. If we make a mistake on this window or crack it Sept. meet is a no go.

I'm the lucky one who gets to cut.

Actually I'm more nimble, flexible and younger. If I fall it won't hurt as much as the old man.

A successful cut, pheww.

The line up looks good.

One pipe cut.

The two bends are done.

The elder one tacking the tubing together.

The straight pipe is tacked in. and all the pipe is ready to weld tomorrow.