My drawing is not a modified ATL unit, but a design of my own. It is to scale and the cage for the puck and ball bolt in from the bottom. Fuel Safe does make a unit that is spring loaded, but it did not work in my application.

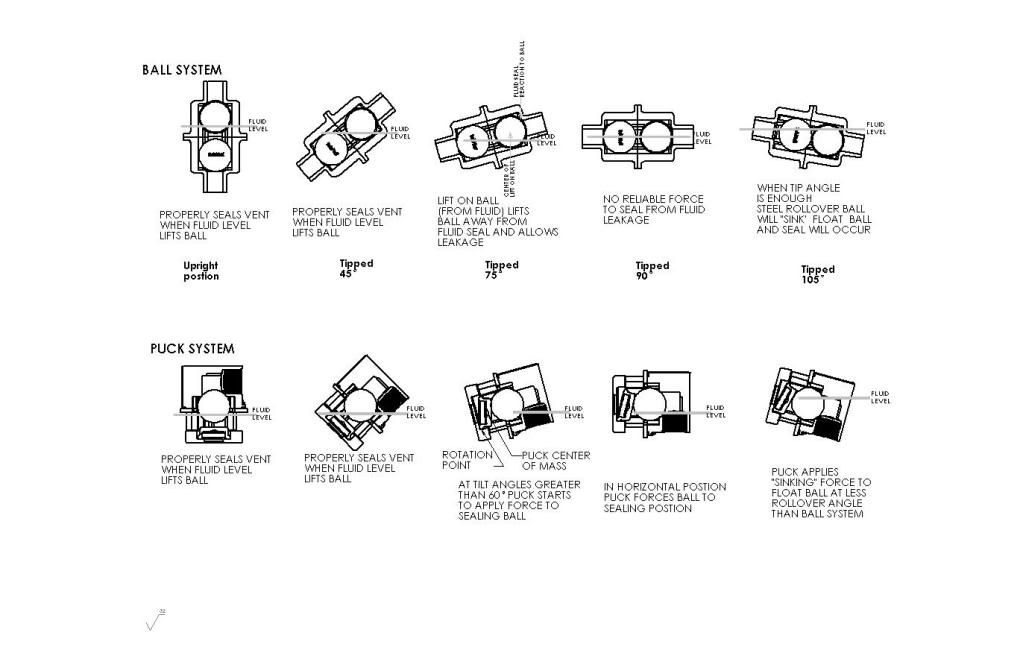

The issue with the ATL type float- and-steel-ball type roll over valves and discriminators is that they are particularly ineffective at near horizontal angles. At angles approaching 90 degrees from vertical, the lift from the fluid is acting to pry the ball away from the lower part of the sealing seat and the steel weight ball is doing nothing. At horizontal, the only sealing action is if the fluid escaping carries the float ball with it. There is no effective force for a sealing action. At past horizontal, the steel ball eventually is heavy enough to "sink" the float ball and create a seal.

I have redesign my valve with a puck and by using a "puck" instead of a steel weight ball, the center of gravity of the weight can be off center from the center of rotation so the force is applied to the float ball at lower rollover angles. In effect, the weight is made to fall "uphill" about 30 degrees before a ball would even start to move. At horizontal, the puck is exerting force on the sealing ball even when it is in its least advantageous position. In actual inversion, the puck serves as a dead weight in the same fashion as the ball.

If any one want, PM me there email address and I can send a pdf of this chart for better viewing. Tony