Bummed about everybody waiting out the weather in Wendover - I'll say it again, not only is it the fastest sport in the world, it's also the slowest.

I'm still tacking toward WOS, but I've had yet ANOTHER monkey wrench thrown into my path.

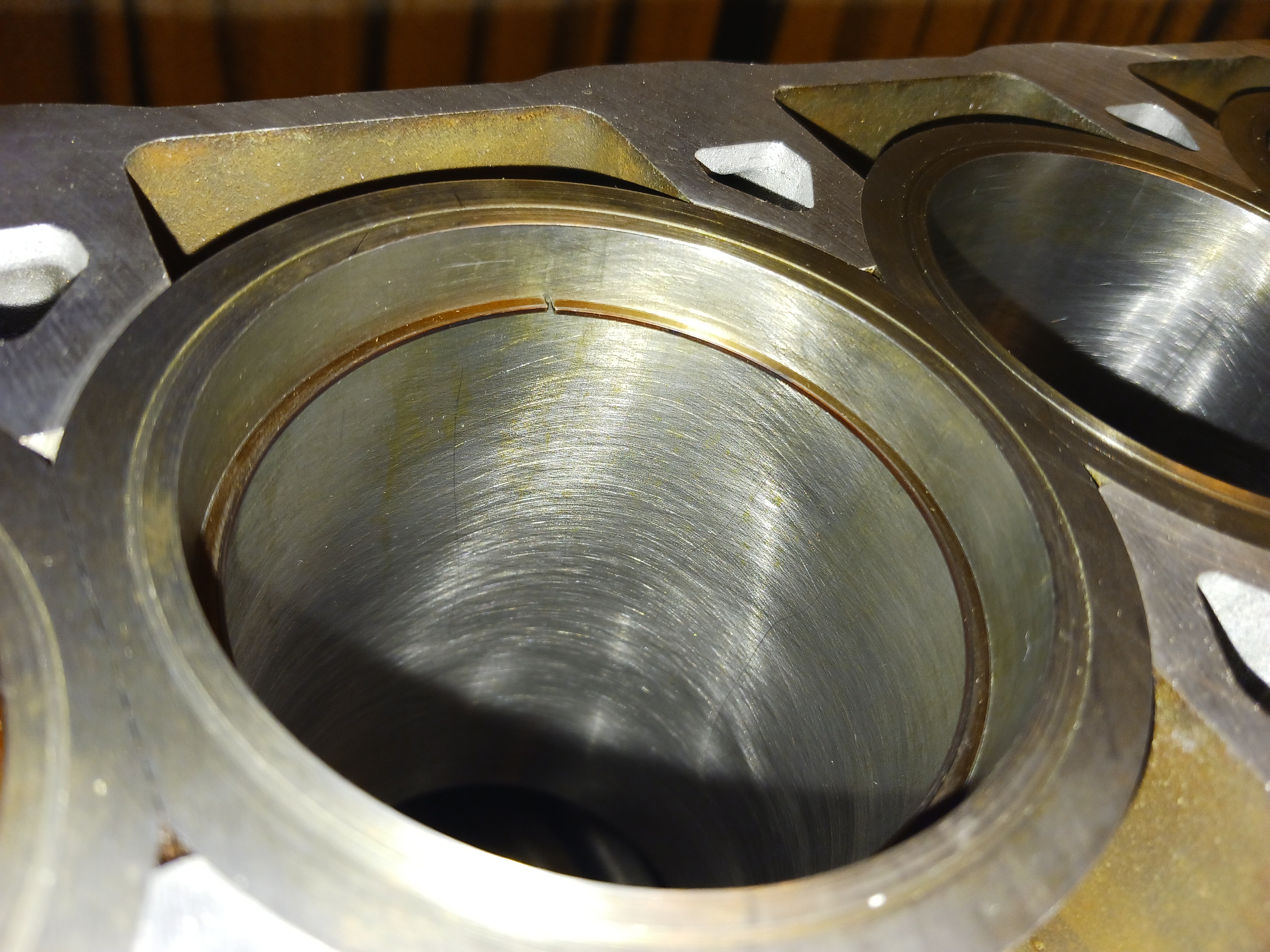

The block came back from Steve Demirjian, and after a .009 haircut, it is square. Mel at C&S was able to squeeze me in for a honing, and by this last Thursday, I was down at T&T fitting rings.

All but one, anyway . . .

20220806_202505

20220806_202505 by

Chris Conrad, on Flickr

It's supposed to look like this older one, which now has too large a gap . . .

20220806_202732

20220806_202732 by

Chris Conrad, on Flickr

My, "GEEZ, I'M IN A HURRY, I'LL JUST CUT IT DOWN" mentality was tempered by the fact that

THAT kind of thinking is what got me in trouble last time. I showed it to Mark, and he suggested that MIGHT work, PROVIDED the radial thickness was the same.

And of course, it WASN'T. The original spec was .105, the rest of the kits were .103-.104. So this outlier was .112, which stood proud of the piston when pressed into the ring grove.

I got on the blower with August at Total Seal, and after assuring himself through a bunch of questions that I was actually able to completely answer, (thanks again, Fordboy) he assured me a correct ring will be on its was as soon as they can get one made. A couple of days, he said.

So now the powerplant is back on hold until I get the correct part.

While I didn't think to check these when they arrived, had I, the engine would be together and likely a day or so from installation.

What I'm wondering is if there's some poor sack out there running with a loose ring, because these oddball sizes are all custom order, and I suspect a complete set with a compression ring that is too small likely snuck its way into somebody else's ring pack.

Good news? I have a trailer again!

I was Craigslisting, and came across what I hoped might be a solution not too far from Road America. It was a 4 wheel utility trailer, smallish, but sturdy. Unfortunately, it was just too narrow to fit the Midget on.

On the way back, I happened across this -

IMG_20220717_130940222_HDR

IMG_20220717_130940222_HDR by

Chris Conrad, on Flickr

IMG_20220718_112129504_HDR

IMG_20220718_112129504_HDR by

Chris Conrad, on Flickr

Used boat trailers in Wisconsin are as common as Camaros at a dragstrip, but this one didn't have a particularly deep "V". It has an adjustable suspension carriage which lets the owner adjust the position of the center of gravity longitudinally, it has brakes, Bearing Buddies, working lights (!) and clear title. For $350.00, he was asking a scrap price for it.

But what I REALLY liked about it is this - I could cut the tongue down, get the Midget on it, and store them BOTH in the garage, saving me the hassle of bothering friends for parking or paying for space.

And after last year's trailer fiasco, an extra pair of wheels offers a welcome bit of mental security. A 5300 lb GVW rating doesn't hurt, either.

A couple of cut-off wheels, new bearings, a new coupler (not shown), a little welding* and a bit of creativity, and I've got a trailer that will haul just about any small sports racer one would care to trailer.

IMG_20220725_133927522_HDR

IMG_20220725_133927522_HDR by

Chris Conrad, on Flickr

*Note - I did the welding, and they looked pretty okay for a change. I've got a Hobart 125 MIG with flux core wire, and in the past my welds looked like crap. But this time, I put in a new spool of Lincoln flux core wire, and all of a sudden, I've got welds I'm not frightened of. I remain no welder, but I can attest that quality wire makes a BIG difference in what can be achieved with a BS welder.