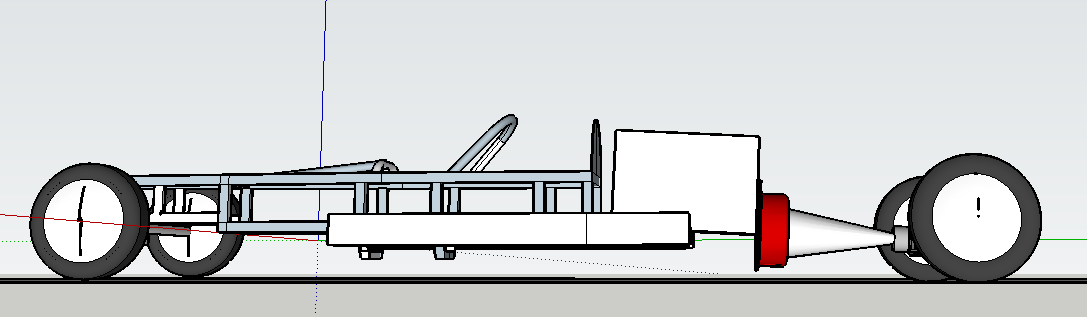

The cutting, grinding, and welding has commenced. The real goal for February is to prepare for getting on the chassis table in mid March. The easy part is ordering axles, tubes and ends from Strange Engineering. The hard part is knowing which width and ends to order. This decision depends on a whole chain reaction of factors.

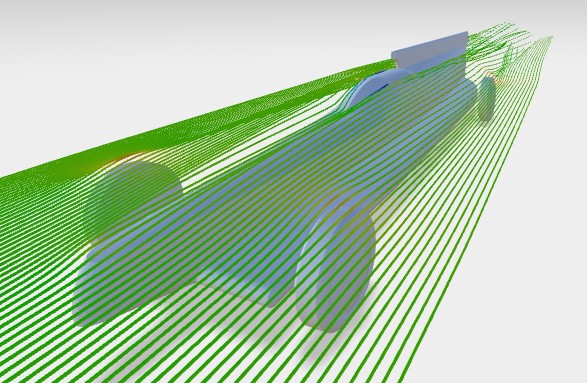

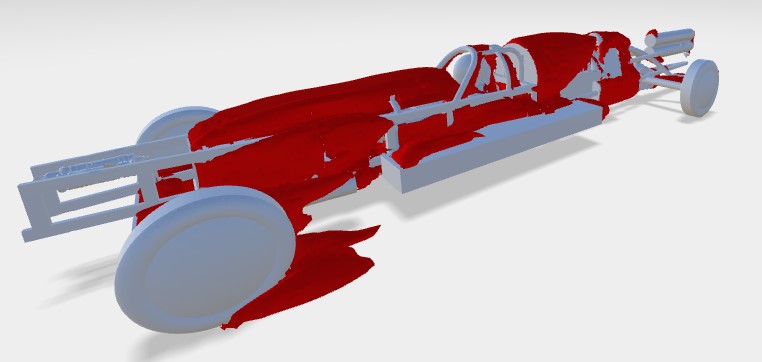

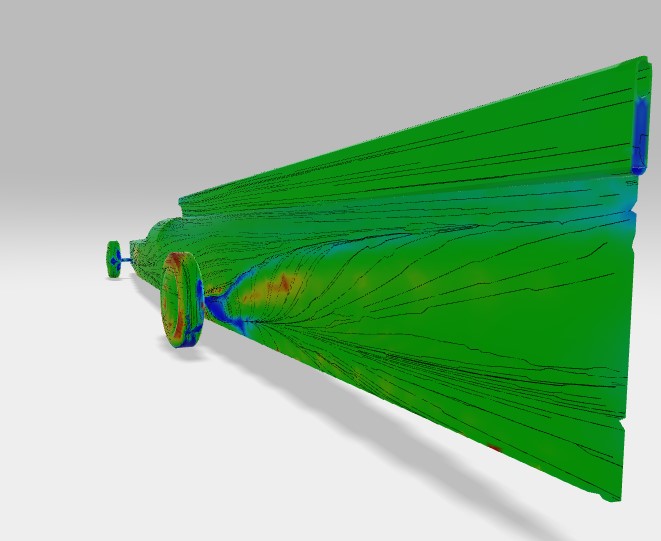

The first axle width variable is the hardest and it's the aerodynamics. Packaging with the side pods is much easier, but what if they require 200hp more than no side pods? For stability I'd really like a wider track width, but at what cost? Then there's the #1 all time lakester controversy: do you want the wheels right next to the body or far away from the body? Seeing that 1:1 scale wind tunnel testing all variants is out of the question for me, the only choices left are relativism (wow that ## car sure is fast) or computational fluid dynamics. I remember back in 2015 I did a test using autodesk flow design using a model built in sketchup. I only had the time and resources to do one test and it was such a hypothetical streamliner idea it did not really matter to continue. This time around I have a few general shapes I want to test.

When I first bought the lakester project I thought that I would go and change the axle setup and wheelbase first and then scan the chassis to put it in CAD and test the aerodynamics. I didn't consider the importance of the track width. Superfastmatt's excellent video series on his streamliner project included CFD testing through a company called AirShaper. I have decided to invest the time and effort now to prepare and test a few models in the month of February so I can make the track width decision with more information. I only ran 3 simulations:

1) Sumner/Rex's original design

2) A narrow track width version with no side pods. The rationale here is that it's unlikely I'd build a wide track version without some storage in the side pod area.

3) A bare tube version showing approximate drag with no body. I wanted a rough idea of drag on a bare version in case I am able to test the car in that configuration at a 1 mile event.

The results of the CFD were that it would require 6.6% more horsepower to go 200mph with the narrow design than Sumner's original side pod design, even considering the reduction in frontal area. The bare tube version requires 93.0% more power to go 200mph than Sumner's original side pod design. I have not decided if I'll publish CD for this project yet, but I will say that Sumner's original design was near the leading edge of the competitor lakesters I've compiled in a database (based on published HP and Bonneville results).

The original design produced 130lb lift, narrow track was 33lb total lift, and bare tubes was 122lb lift. Ideally there would be a couple hundred pounds of negative lift at 200mph so there's a lot of room for improvement here. There's a lot of caveats in this very amateur analysis and this certainly shouldn't be used as proof that wide wheelbase is faster than narrow wheelbase.

I don't know if these results are within the margin of error. CFD is not the ultimate measuring tool, but that's the best information I have to work with in this case. I'm going to continue running CFD simulations throughout this project while working from a perspective of shapes that seem to work in what appear to be the most efficient lakesters. Hopefully in a couple years the great white dyno can judge for real.

The second axle width variable is the existing front axle and wheels that came with the car. While there have been a few notable exceptions, the general rule I see used in construction of other lakesters is for the rear tires to follow in the hole in the air left by the front tires. This seems to be more important the further the wheels are from the body.

Sumner did a great job of modifying some dodge hubs and ordering a set of offset front wheels to reduce the scrub radius, but this moved the wheel closer to the body than can be used due to interference with the back of the tire into the side pods. Another problem that would not have been an issue for Sumner but is a problem for me is that the front spindles and hubs are not set up for front brakes.

Front brakes are a requirement for ECTA events. While disc brake kits exists for 37-46 ford spindles, all that I have seen have cast iron rotors and I would like to believe that this car will approach speeds and forces that may compromise cast iron rotors. Making my own caliper mounts and using aftermarket rotors appears like the only choice.

Putting the car in CAD also revealed another issue before the engine swap. The winters axle puts the axle centerline well above the driveline axis (about 3 7/16"). Because the driveline is bolted together and relatively short, this puts the engine, transmission, and axle at a pretty severe angle tilting rearward and the bellhousing clearance to ground is far closer than I'd like. This is all assuming the use of the 26" rear tires that came with the lakester. I can only think of the following paths forward:

1) Run 18x30's on the back. I haven't priced those wheels/tires but I can't imagine this being the cheap option and would seemingly have more aero resistance. Setting the car up this way also requires a more exotic 19" custom wheel and tire for 1 mile land speed racing.

2) Use the GM 7.5" or Ford 9" axle and pinions provided. I'm not very invested in the winters now so it'd be a good time to swap before ordering axles. The cons here are the hassle between changing gears for short courses and I'm afraid I'll break/shock a 7.5" on concrete with the power I'm hoping to make. The 9" is not available with the gear ratios I'd like to imagine I'll need at Bonneville with a 26" tire. This also does not fix the bellhousing height problem but going to a 28" tire could be a compromise.

3) Go to a nascar reverse starter style bellhousing that is shorter like the quartermaster low ground clearance unit. The trouble with that particular unit only uses a 5.5" clutch and quartermaster does not sell a blank 5.5" and I already have a blank 7.25". If I could find a bellhousing that would allow a 110 tooth mini nascar flexplate to match the 7.25" clutch I think it could work. I can angle the whole engine back because it'll be drysump anyway. Transmission and axle oiling may have to be addressed.

4) Spend all the time and money on the front end for the rear end. Set up the car to run both a Winters for short track testing and the GM 7.5" for Bonneville all while it's on the chassis table. Optimize for the 7.5" in terms of pinion to axle offset and pinion length. Relatively high axles in short track also require taller tires which will be helpful for traction anyway. I think there are some 15" wheel & tire options that can work for this application. Order axles for the GM 7.5" wider than the Winters so that the brakes can hide better inside high offset wheels. I'll have to sleeve the OE 2.5" OD tubes with 1/4" wall 3" OD axle tube to fit appropriate axle ends. Option 4 feels like the right choice and is my current plan.

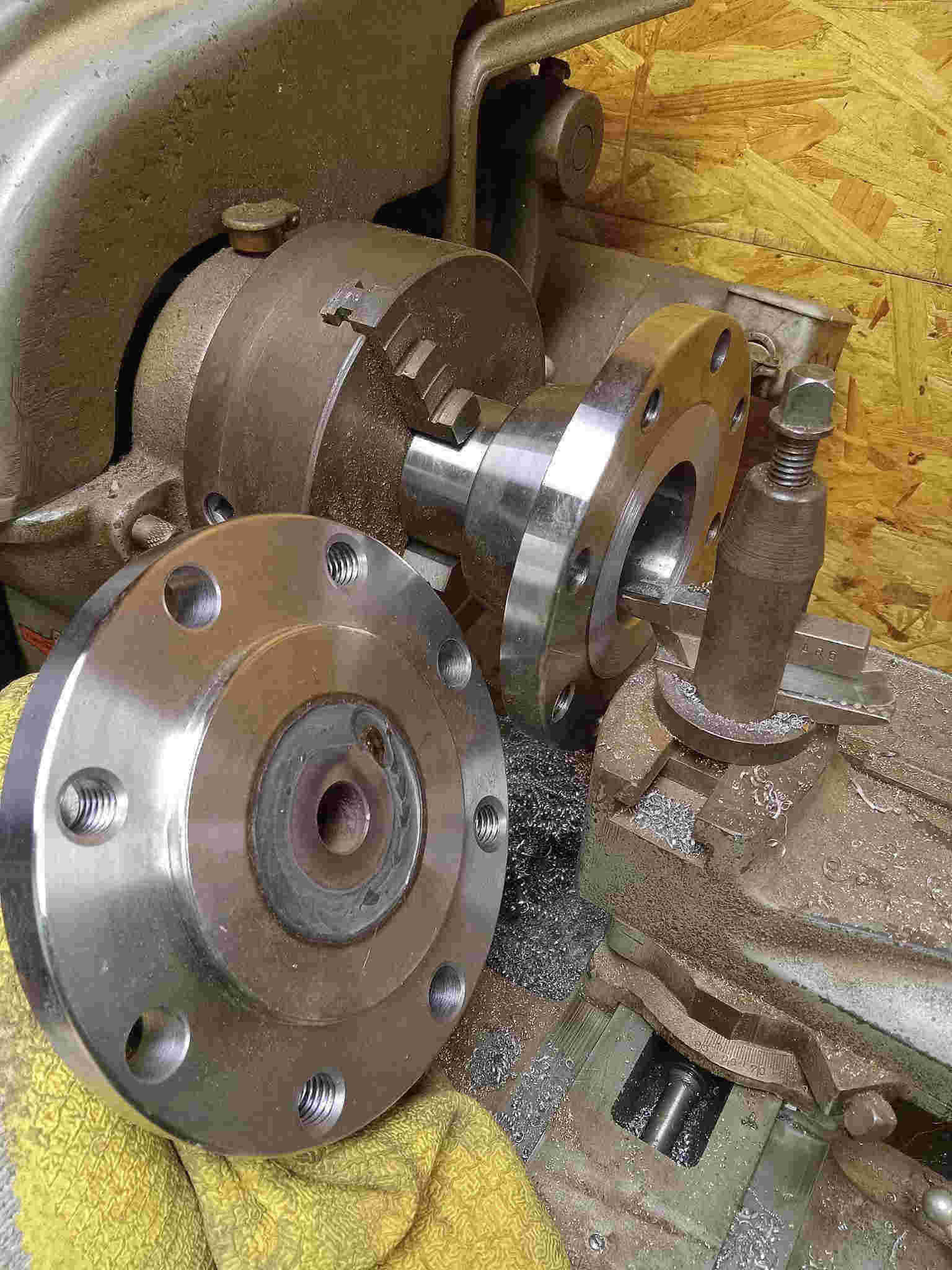

I sold my lathe in the move but managed to buy a small atlas craftsman 10" lathe in an estate sale locally. I was able to machine the driveshaft adapter on the axle side to register the transmission side and then I also had to cut a custom washer to take out the slack on the winters input shaft. The original washer had some foamy glue on it. Any idea what glue this is and what I should use to seal this joint before final assembly?

I bought an open box AC TIG machine last month and have been trying to teach myself TIG. I feel confident in my MIG ability and have learned what's good enough and needs work after years of endurance racing and hobby experimenting. In the last month I've been tinkering with little projects like fire pit stands and repairing tools for family so that I can at least get used to where the tools are now and organize them efficiently. Mission critical weldling like the header will be have to be farmed out to a pro but at least I can fit up the parts on my own.

Last but not least for January was a swap meet. I managed to buy a set of Strange steel drag brakes with high temp pads for all four wheels, two sets of winters quick change gears that'll suffice for testing, a drysump pan I can use for parts, and a trick flo GM 7.5" braced differential cover. The strange brakes are actually the dual caliper for the back of a dragster and I managed to score a separate, but matching set of rotors. The axle ends will have to be the strange symmetrical style in order to use the bracket but it means at Bonneville I can run the dual caliper setup which hopefully would spread the heat input and give me double the power until boiling high temp brake fluid in the event of a chute failure.