I spent some time staring at it last night. Quiet contemplation.When I made the fuel tank that is in it I underestimated the hassle value.I suspect I have since allowed the true value of the hassle to diminish in my memory...... There is a dim light blinking at the moment and it has a dymo label under it that says "warning, time wasting imminent" .....I don't want to spend the time and money on making a new tank when I know for a fact that other things are going to come up and there will be a fix for the current ills of the fuel tank, and someone out there will know what to do.

Just to reiterate , the fuel pump ,a Bosch 580 254 044 carked it after a life of about 1 hour running time....we suspect that it was cavitating, but I still won't rule out a foreign object such as a dag of epoxy , or Al or whatever..It is clamped in a beer can size clamp that doesn't pinch it, there are heat shields so it is not subjected to any extreme radiant heat, it has the correct gauge wiring

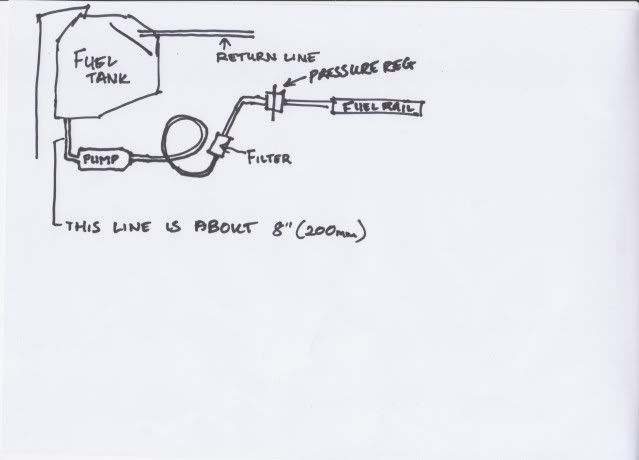

Below is a diagram drawn with a thumbnail dipped in tar...note there is no filter before the pump, no sock in the tank.The breather runs off from top left.There is a splash guard against the return line and also a cross shaped piece over the outlet to stop swirl.....

.***EDIT****I might have to check that again....the filter may be between the tank and pump...it's currently disassembled and at a glance I

thought that was how it went together but I msy be wrong, anyway.....who thinks what will help is important.

The tank is epoxy lined so if I have to cut it I might as well make another one because I won't be able to weld anything to it...

Who has suggestions as to whether an additional filter would help?,

would a swirl tank help?,

would longer lines before the pump help?.

HELP PLEASE!!!!

PS: It's OK to be brutal