I think he posted this but Rich ended up turning down the OD of the studs

Last Friday I stopped in to see Rich before heading down to LA. I helped him set the head on the engine. During the week he torked down the head.

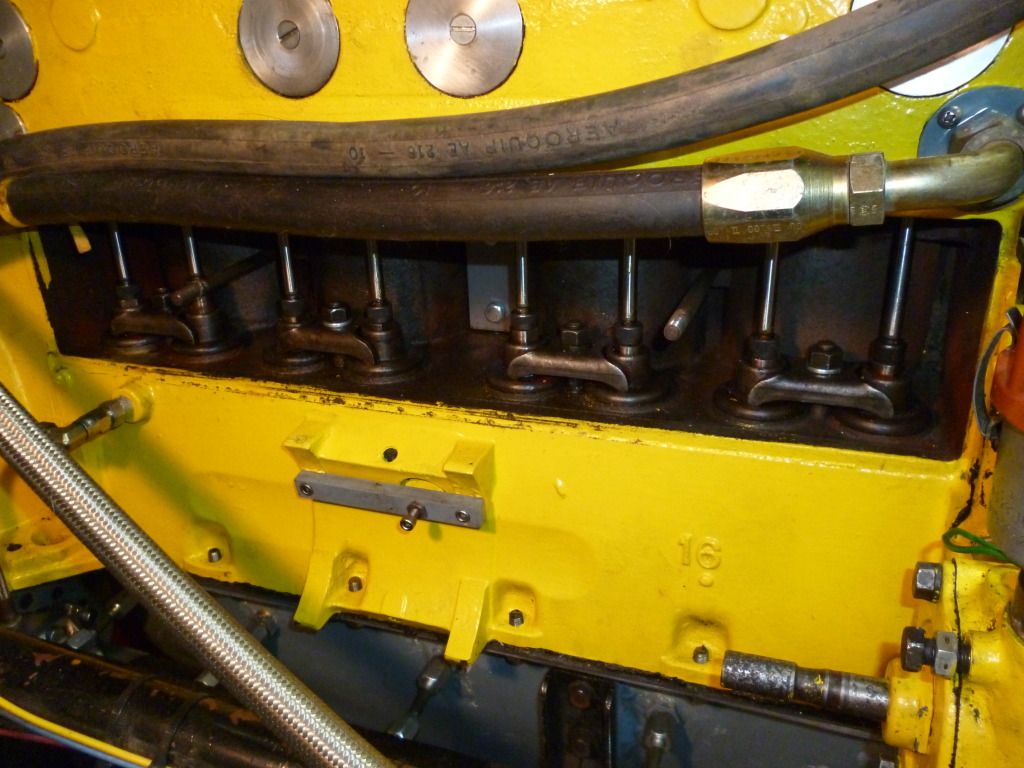

We started off today by switching around the end rocker arms because the pushrods were either too close to the hole in the head or already rubbing a little. The roller is slightly offset so just spacing the rocker to fix the pushrod issue caused the roller to be not centered over the valve

Before, Front rocker, roller view

Before, Rear rocker, roller view

One stud on the rear of the engine and one stud on the front of the engine needed to be removed to take off the rocker arm. After the retainer was removed of course!

The spacers had to be switched around and one of them modified a little

After, Front, roller side

After, Rear, roller side

The angle on the second pic was off, but the rear was still a little off the valve. The main issue which was hard to see anyway was the rubbing of the pushrod on the head and that is now fixed!

After the rocker assembly was back together we set the valve lash, .026 intake and .028 exhaust, as per Dema Elgin’s instructions. We chatted about it for a while because it seems like a lot when you are double checking everything. Rich was going to call Elgin and ask why the lash was so great. We figured it must have to do with allowing the pressure to not come on until the lifter is off the steepest part of the ramp on the cam lobe. I am certain someone will chime in.

Next Rich moved on to bolting on the intake

Here he is making the gaskets

Intake assembly bolted on

The fuel line needs to be made up to finish the intake, that will wait for another day

Dodge/Morton & Brett problem of the day, oil return issues.

Here are the pics with explainations

First is hard to see but remember this pic from a while back, it is a detail shot of the M & B head where the rocker shaft assbly mounts. Notice the raised areas in the casting where the original rockers mount?

Now look at the way the aluminum plate that forms the base of the rocker assbly sits

The oil needs to drain over the aluminum plate to drain into the lifter gallery.

Here are some pics of the lifter gallery. Look closely for oil return issue #2

In case the pictures are not clear…..there is no provision for oil to return to the bottom end!

After discussing different options, like disassemble the engine and drill some holes, run lines from the side cover and valve cover to a hole drilled in the distributor drive housing, Rich decided to drill a return line into the cover for the through hole between the #2 & #3 cylinders.

The plan is to put a “T” fitting on the return that Rich put in the unused intake port in the block.

Here is a pic

I am sure Rich will think about it during the week and perhaps have another answer or finish off the return we discussed.

In the meantime, some motivational pics

One last pic of Rich taking a break and thinking about the oil issue.

At this point we took a drive up to the shop where Rich’s bantam is being worked on….but they weren’t in today.