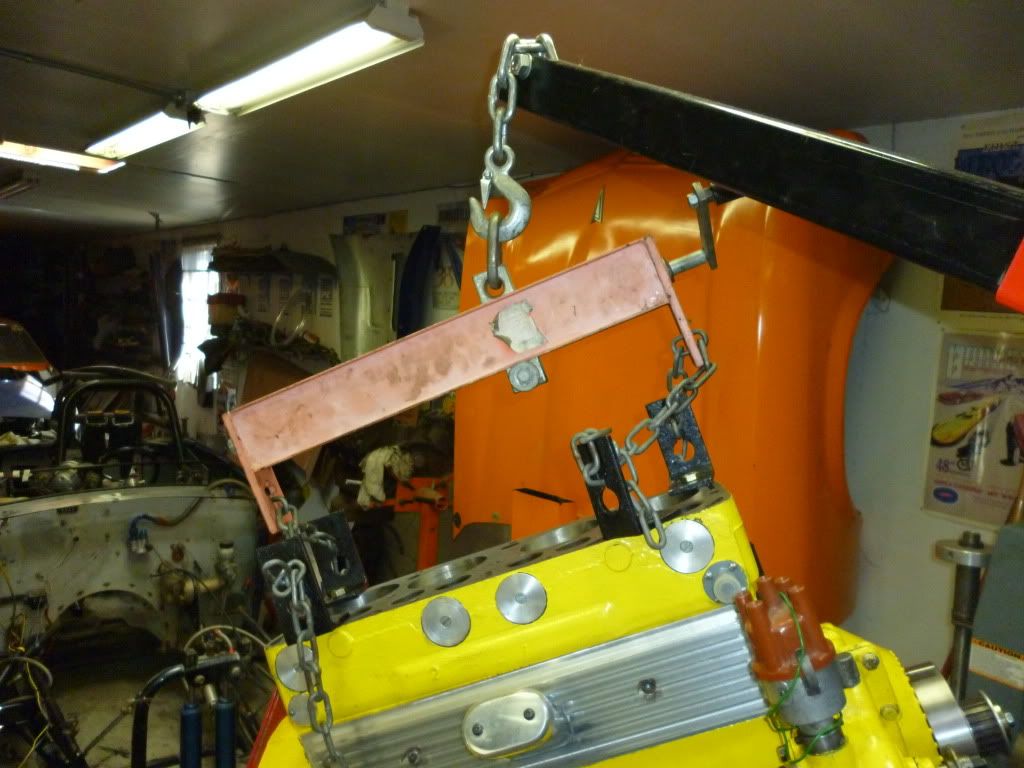

Update, I was at Rich’s on Moday, MLK Jr day. Rich made part of the brackets to mount the engine, some neat little accessories for the engine tilter that would allow us to slip the chain onto brackets rather than have to bolt it to the block. And he added an actual handle, which it has never had because it wasn’t in the box when I bought it.

The goal today was to remove the engine to add a spacer to the clutch fork fulcrum to allow the clutch fork to engage the clutch easier, and hopefully before it bumped into the firewall. Also the goal was to fabricate the engine mounts so the engine is actually mounted in the roadster.

We started by lifting the engine and setting it in the position we wanted it in

Level from side to side, 3 degrees from front to back-even though the engine will be fuel injected, mechanical of course!

Once the engine was leveled, we bolted the first part of the engine mounts to the block and then the “doughnuts” to the frame with the second part of the steel bracket attached. Then I tacked them in place. I didn’t get any pics because I was welding. But here is a picture after the mounts were tacked before I finished welding the first one. The steel parts attach to an aluminum collar or “doughnut” which is attached to the frame. Rich never welds to the roadster frame because he has put so many engines in it.

Here are the mounts from different angles

Once the mounts were ready the engine had to come out again

Here is a close up of the leveler with the brackets Rich made and the new “handle” for turning the screw

I guess I didn’t get pics, but we looked at the clutch fork and decided that a ¼” spacer was the place to start for the fulcrum. We lowered the engine on the hoist and pulled off the trans and bell housing again. It went smooth. While I was looking around the shop for the hood sides ( which were right in front of me on the wall), Rich made a ¼” spacer and had it bolted back on. So we but the trans/bell housing back on the engine and put the engine back in the roadster.

Here is a couple of pics which show where the clutch was before and where we wanted it to be. This is pre- spacer

This is where we want it to engage ( I am holding it)

Here it is back in the roadster, after the spacer is installed on the fulcrum, with the engine bolted into the car

Here is the before

I think that is an improvement!

Here is where Rich turned out the lights, quitting time. Engine bolted in with solid mounts, clutch fork positioned where we want it.

The Montana dodge boys are coming to visit Rich next weekend. Should be fun, don’t know if I can make it but I hope to.