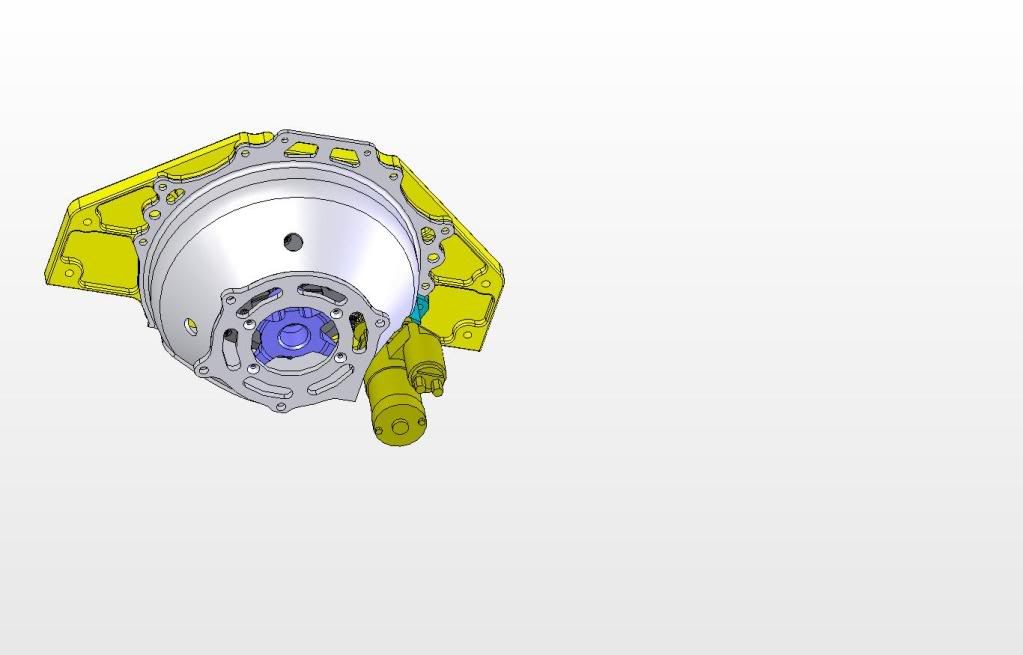

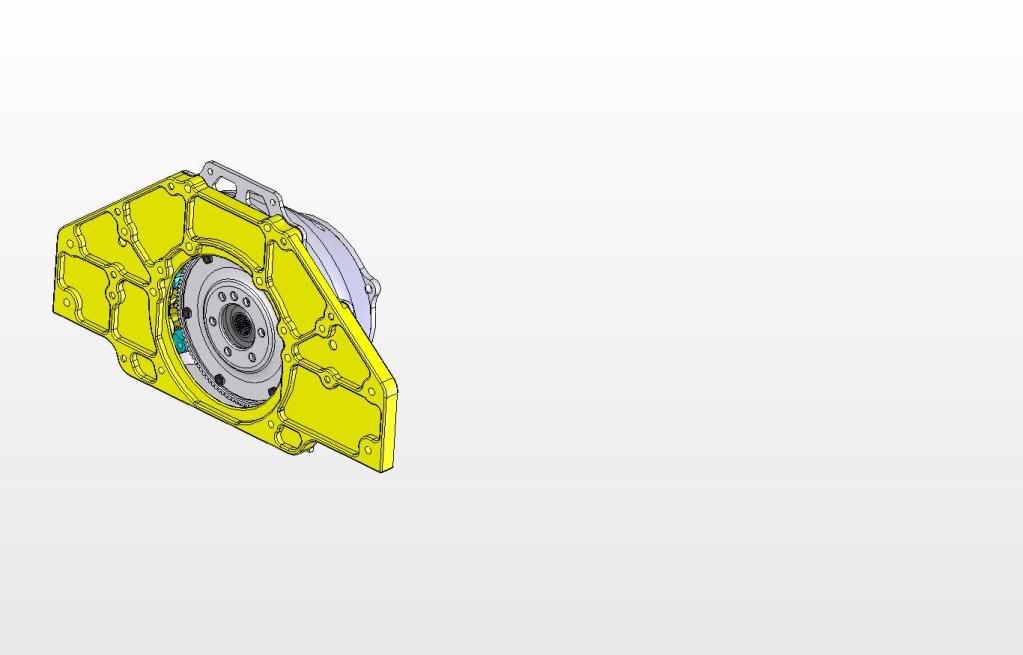

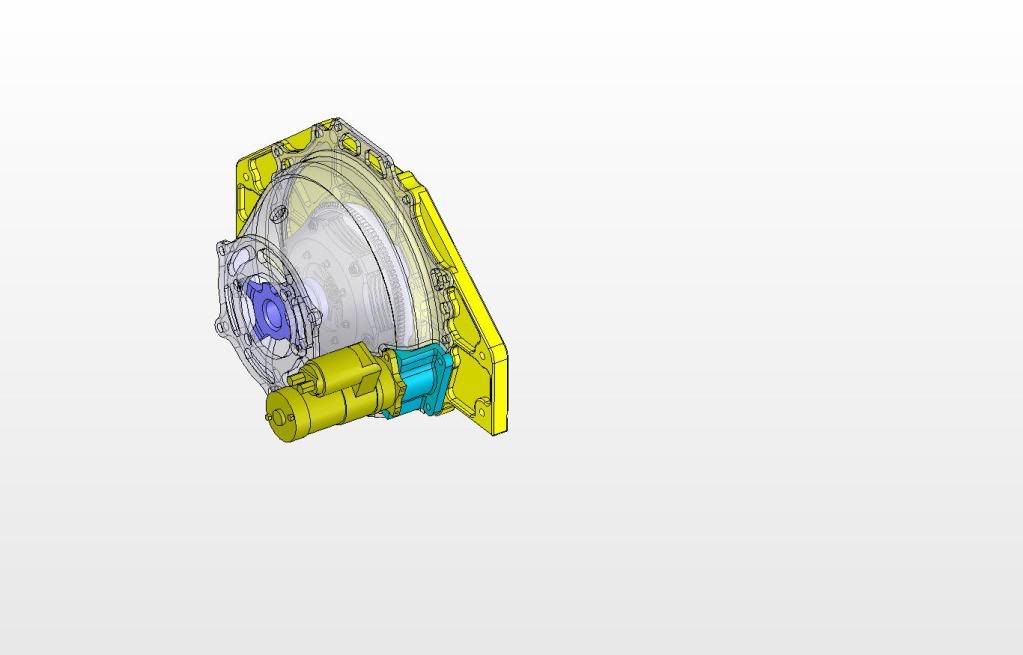

This is the preliminary bell-housing scheme. I will still need to fine-tune everything. Originally we were going to weld a bell-housing together, but after looking at what is available we were able to find a unit by Quicktime that could be modified. Due to ground clearance issues we went with a 110-tooth flywheel and clutch combo and had to flatten the bottom of the bell-housing to make it all work.

To clear the reverse mount starter it would have taken a major hole in the bell-housing and instead we used an adapter to mate the starter directly to the mid-plate. This will eliminate tolerance and weld deflection issues with the bell-housing and makes “tuning” the starter adjustments to the ring gear straightforward and reliable.

This particular mid-plate is designed for the GMC 6 and the Chevy / Aurora IRL engine. We also have one with a SBC, BBC and V4F pattern.

I want to thank Quicktime for sending us a drawing of their bell housing to work with. Tony