Saturday we took the sleeves out and as always there's a challenge in there somewhere.

As I was pulling the third sleeve I broke the sleeve puller.

The next five sleeves we had to beat them out.

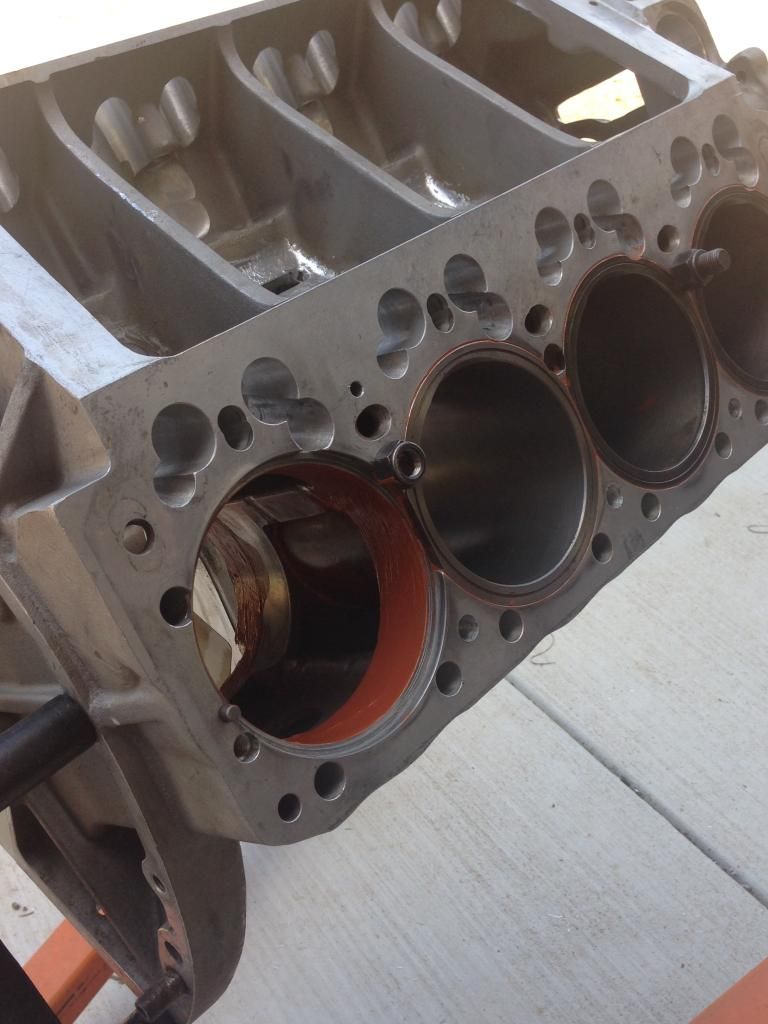

After a good cleaning of the block we installed the sleeves on Sunday.

We out plenty of high temp silicone on the sleeve and block to make sure there's no water leaks.

A little help from the attitude adjuster and they went in just fine.

No we need to take the block to get the sleeves bored. The thrash is starting.