I went down the Carrillo road with the 175 single Bo, that bike

may get finished when I repair the 250.

Fordboy, since stripping the crankcases and checking oil galleries for reasons the main bearing shell failed (no damage to the journal), I found none, clean as a babies bottom.

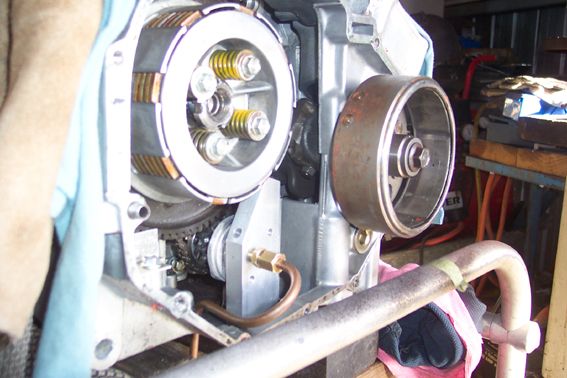

When setting up the piston oilers I fitted an aux. oil pump, just to feed the squirters, but after testing I decided that the aux pump would not be needed,,,I guess that decision was wrong.

Pressure dropped from 70 psi, to 50 psi when the squirters were activated( something else I forgot to do during the run), the pistons survived without oil cooling.

I have found most of the bearing shells I need, with exception of one rod set for the replacement rod (the damaged cylinder's rod now has some slight twists in it).

The head took the brunt of the force, sparing the crankshaft from visible damage.

This bike has the same financial limits all of my projects have, keeping fun as the 1st priority, and doing the best I can, given the realistic goals I have.

Throwing cubic dollars into the engine

might lift the bar, but until I sort the setup I have, or some fool wants to waste some sponsorship dollars on it, I'll use the KISS method.

A boost increase to 20 psi might not hurt (much) after all, Dave Plecas has boosted his stock bottom ended CT110 to 45 psi, without failure,,yet (111 mph in 2014)

Tiny