Thanks Maj; It's going to be a pain to maneuver, trailer for the return road etc.

I was planning on using double acting master and slave cylinders or pull cables on either side for steering to make sure I got no bumpsteer.

The rules state fixed, gear or linkage, what is the history behind that?

I can see single cable where on direction relies on a push motion being not so cool.

Is this something worth enquiring or am I wasting my time?

Any linkage system I make will have some bump steer when not straight ahead.

Bump steer on a bike with relatively heavy wheels spinning at a reasonable rpm is something I would prefer not to deal with.

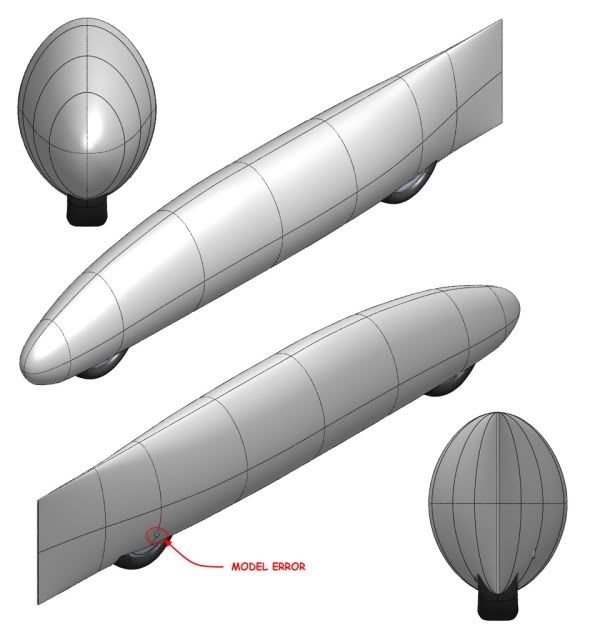

More email tag with Woody tidying up the model for CFD;

Thanks

jon