I managed to get to the local Pick-N-Pull junkyard for the 1/2 price sale this weekend. I think I got all the suspension/brakes that I will need for the Rampage. I was going for new front knuckles/hubs, struts/springs, and all new rear stub axles and brakes.

The reason for the swap-over from the stock rampage stuff if for several reasons... By using later "K-Car" front knuckles and hubs, they will work like drop spindles compared to the Rampage knuckles. The centerline of the drive axle is about 1" higher in relation to the lower ball joint. The K-Car knuckles also use a bolt-in bearing carrier which is stronger and more reliable than the pressed-in bearings on the Rampage setup. The K-cars also use a 5-lug on 100mm bolt pattern which will allow me to use 15" 5-lug wheels, instead of the 13" or 14" 4-lug Rampage configuration. The brakes are also bigger, but I don't think that will be much of an issue for this Rampage.

I also grabbed some 1st generation Neon struts and springs, which will give a significant drop to the front end, and are a nearly bolt-in deal (just drill 1 extra hole in the upper fender where the strut mount attaches). The 1st gen Neon will give the lowest ride height available from factory parts. 2nd gen Neon would be a bit higher, and the factory Rampage springs/struts sit higher than the 2nd gen Neon. If the whole thing is too low (which I doubt), then I will change over to the 2nd gen Neon.

In the rear, I pulled the stub axles, backing plates, drums, bearings, etc. from a '90-something LeBaron. Again, I get the bigger brakes and the 5-lug setup to match the front.

Here is one of the backing plates for the rear. It must have been my lucky junkyard day, because it looks like these brakes have been recently rebuilt with a new hardware kit, wheel cylinder, and fresh shoes.

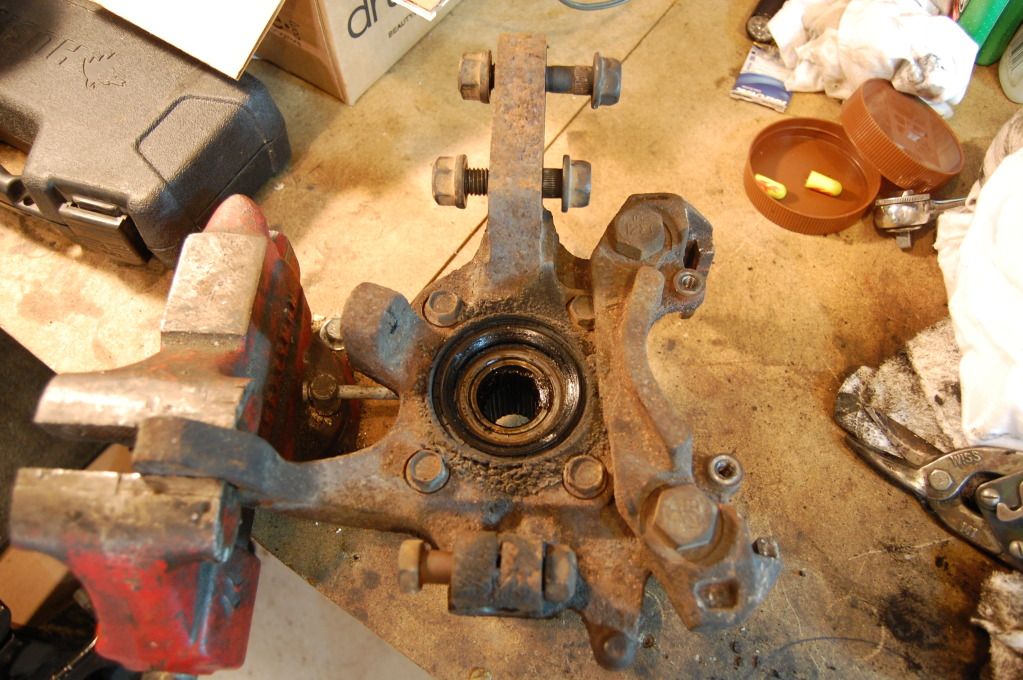

Front brakes, knuckles, and drive axles are from a '93 Plymouth Acclaim. They are in decent usable condition, needing a good wire wheeling, bead blasting, and some fresh paint before being installed.

This is the "Hot" setup for L-bodies like the Rampage, Charger, Turismo, 024, etc. These parts are much more heavy-duty than the stock L-body, and offer the improved geometry. Here's a look at the back side of the Acclaim knuckles, showing the 4 bolts which retain the bearing and drive hub. Since these photos were taken, I spent a couple of hours cleaning, degreasing, wire-wheeling, and generally de-griming these parts. It was a hot, sticky, dirty, gritty weekend.