Long Awaited.....perhaps

Here we go. Well....in my mind today was a very straight forward cut a step around the ports, fit the aluminum block, and tap some screws to hold the aluminum block in place kind of day.

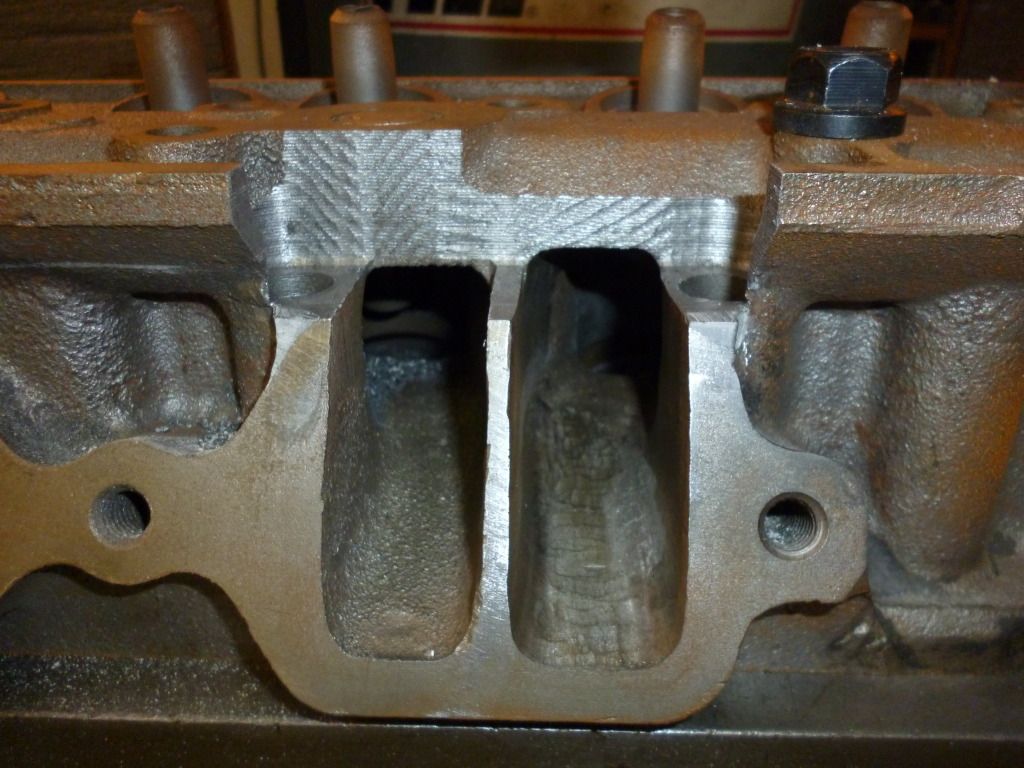

Started off like this

Block fits, so far so good

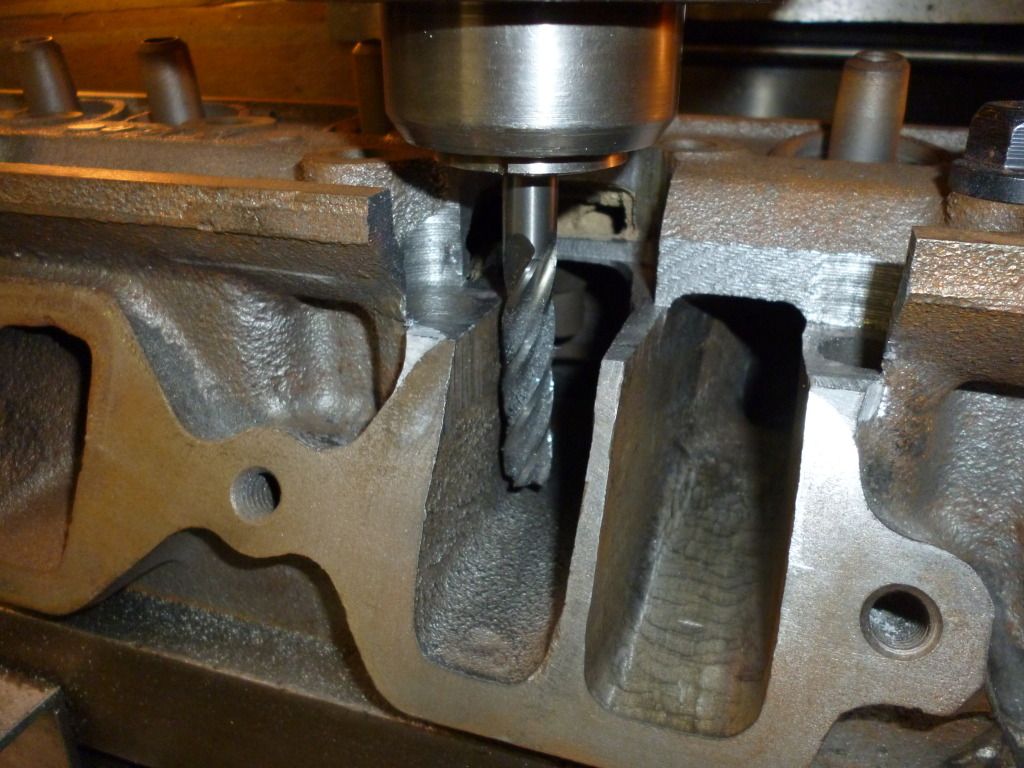

Little more milling....

Nice!

Another view

Good right? Well Rich came over from working on his 26 Dodge engine and we talked a little about the head. I mentioned that I wished I could push it a little farther.....to try to get over the valve more. Rich said, just do it on one of the ports, it is now or when?

Point taken

New end mill in mill, cut on sir, cut on

At around this point I started forming the notion that if actually doing this modification to a head to run, the block would go longways, and probably incorporate the rocker shaft monut/headbolts. This block wasn't long enough and I decided to keep it "simple" (

, simple..yeah right ).

More cutting, the cut is moving farther back toward the valve

That is as far as I could move it, the spring pad is right there now, and I think some guys here are cutting larger spring pads for their valves so they can use larger springs right?

I machined the aluminum block to fit, needs just a little more.

That is it for now. May be a week or two before more updates.